Are Version 2 and 3 Airsoft Cylinder Heads the Same

Are Version 2 and 3 Airsoft Cylinder Heads the Same

The cylinder associates is the second half of the compression component in an airsoft automatic electric gun, the other half being the piston associates.

Together, they work as a pneumatic system that serve the office of transferring force from a spring to propel projectiles called bbs through a butt.

The cylinder assembly is one of the easier parts to put together. Most aftermarket vendors will label each piece for compatibility. Despite this, upgrading an Airsoft AEG is rarely as simple as picking out components, and there are still key points to keep in mind to maximize fps gains and preclude feeding issues.

For those who want a more visual experience, I cover the adjustments and modifications to the cylinder set in the post-obit video. However a lot of the details and reasoning is left out, so I highly recommend that you lot still read through this entry to improve grasp the idea backside the actions carried out.

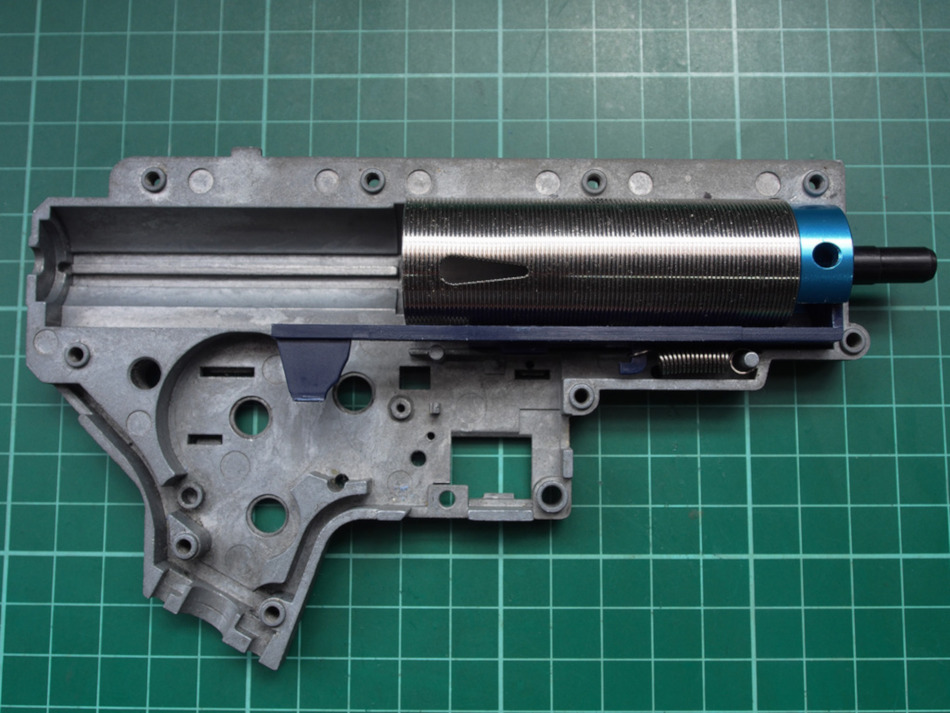

The cylinder associates is mainly composed of the cylinder head and cylinder. Nonetheless, aiding in the loading of bbs into the hop bedchamber and transfer of air into the inner barrel, we have the the air seal nozzle and tappet plate. During installation of the cylinder assembly, these 4 parts are installed together as one unit.

Cylinder Head Grooming

At that place are different versions of cylinder heads for different gearbox versions. Depending on the AEG model, information technology can have different variations of gearboxes.

The TM G3 uses a version two gearbox so we have to use a version two cylinder head every bit well.

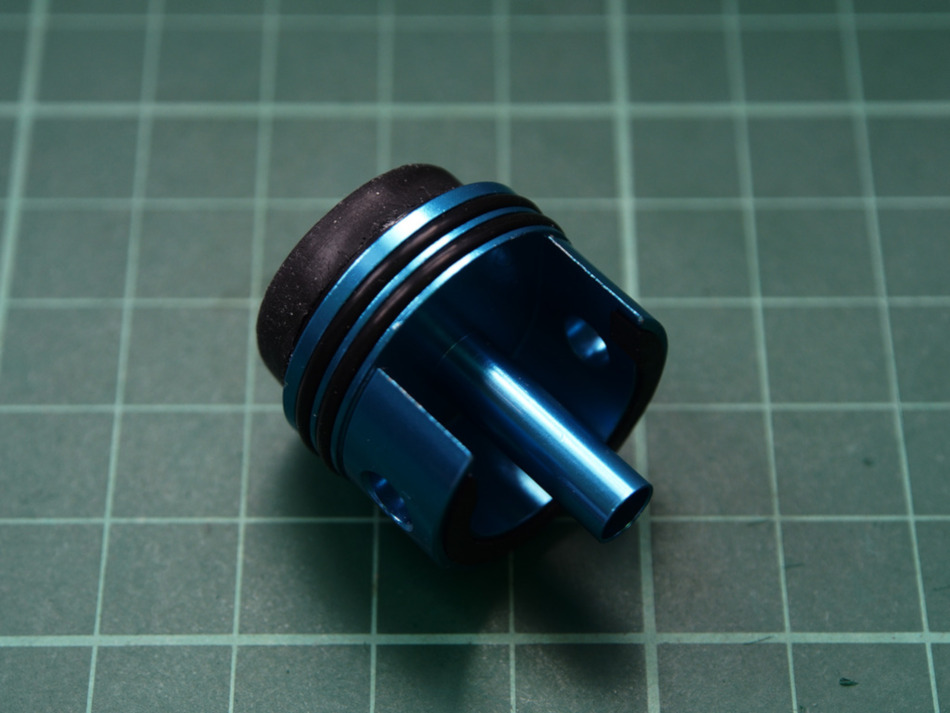

Stock AEGs will usually come up with a polymer cylinder caput. I find them to be quite durable, but may crack eventually when using a heavy leap. Aftermarket ones are usually a sort of alloy or metal similar contumely and tin can have a different number of o-rings to make sealing easier.

The impact cloth at the dorsum comes in different configurations. Flat, concave, or a mixture called tapered. The concave shaped rear is more common with cylinder heads designed for bore-up sets which use mushroom shaped piston heads now referred to equally silent piston heads.

Choosing the right cylinder head is more well-nigh what version gearbox your aeg is using and less almost functioning gains. I accept found that single o-rings can seal but as well as double o-rings and the flat touch on cloth is easier to piece of work with when installing sorbothane pads.

Installing a Sorbothane Pad

Sorbothane is a very good shock absorbent textile that will assist us reduce stress on the gearbox from the piston's impact. They can be bought pre-cut or in sheets and come in different stiffness ratings called duro. We are using a stiffer 70 duro pre-cut pad that's 3/16″ in thickness, from here, that'due south less likely to deform and change our angle of appointment (discussed in P1 – Piston Preparation).

Despite the Lonex having less surface area for the Sorbothane pad, we will still exist using this over the stock Chinese clone to observe how the pocket created by the uneven contact patch affects operation and durability. In the worst case scenario, I wait the pocket to create back pressure against the Sorbothane pad as the piston pushes air through the cylinder head, somewhen leading to the Sorbothane pad'southward removal.

Scatterplot has released a new version for employ with Lonex cylinder head since my concluding buy that fit ameliorate which they refer to as tapered v2/v3 pads.

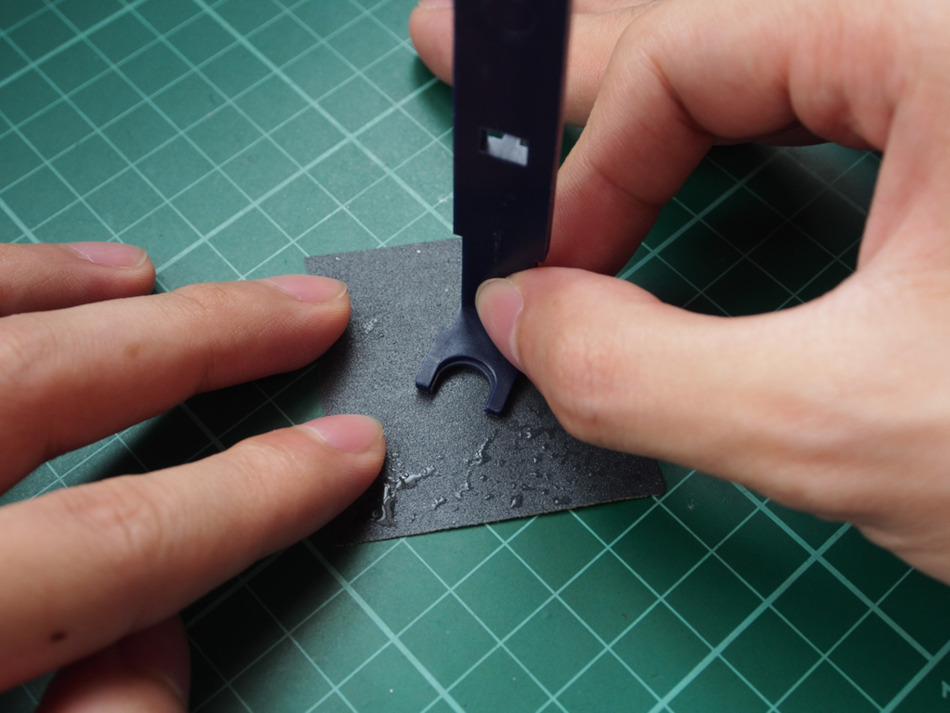

Moving forward, the beginning affair we have to do is prepare the cylinder head by roughening upwardly the surface of the bear on textile behind the cylinder caput. We will do the same thing on one side of the Sorbothane pad and then stick these scored surfaces together using superglue while being careful that the holes of the pad and cylinder head line upward properly.

Another way to do this is to remove the existing impact material, score the cylinder head, and then apply the Sorbothane pad directly. However, since we are using the Sorbothane pad to correct for AOE also as shock mitigation, nosotros will non remove the existing affect material.

Cylinder Type

The cylinder acts a reservoir that holds the air which will be used to propel bbs. There are designated cylinder types that hold different amounts of air volume. Y'all can place them by type and the change in the air volume is adamant by the positioning of a port, or ports, on the cylinder walls. These ports also maximize the spring'due south potential by allowing the piston assembly to accelerate further past the port's location before compression slows information technology downward.

Typically the choice of cylinder is a affair of picking out a cylinder blazon which manufacturers accept identified and approximate works with your AEG or barrel length. These days butt length is predominantly the determining gene as manufacturers take realized that modded AEGs can come in diverse dissimilar lengths.

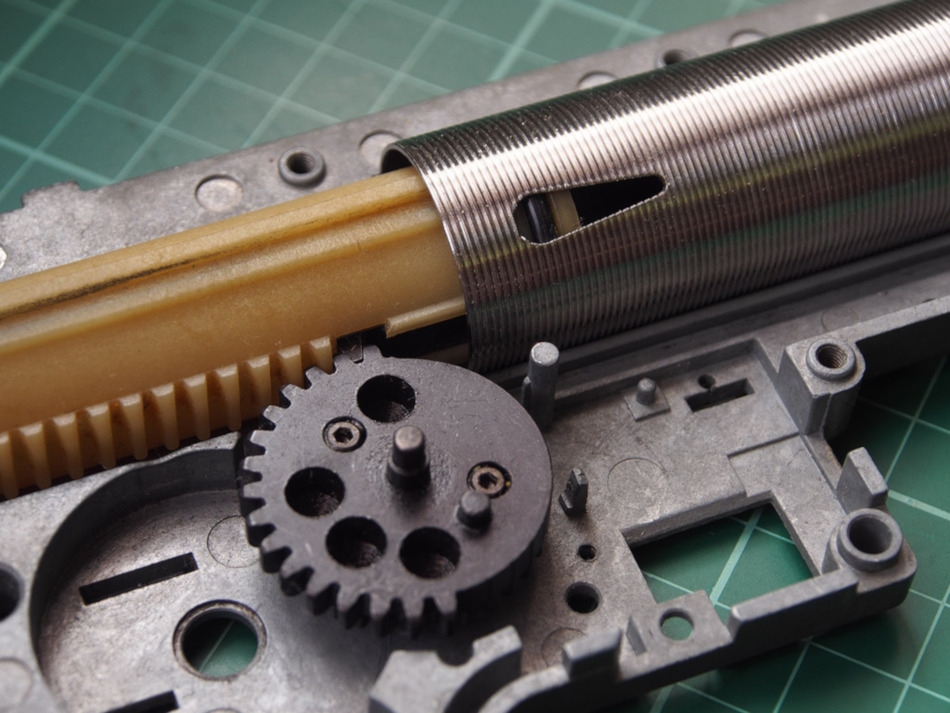

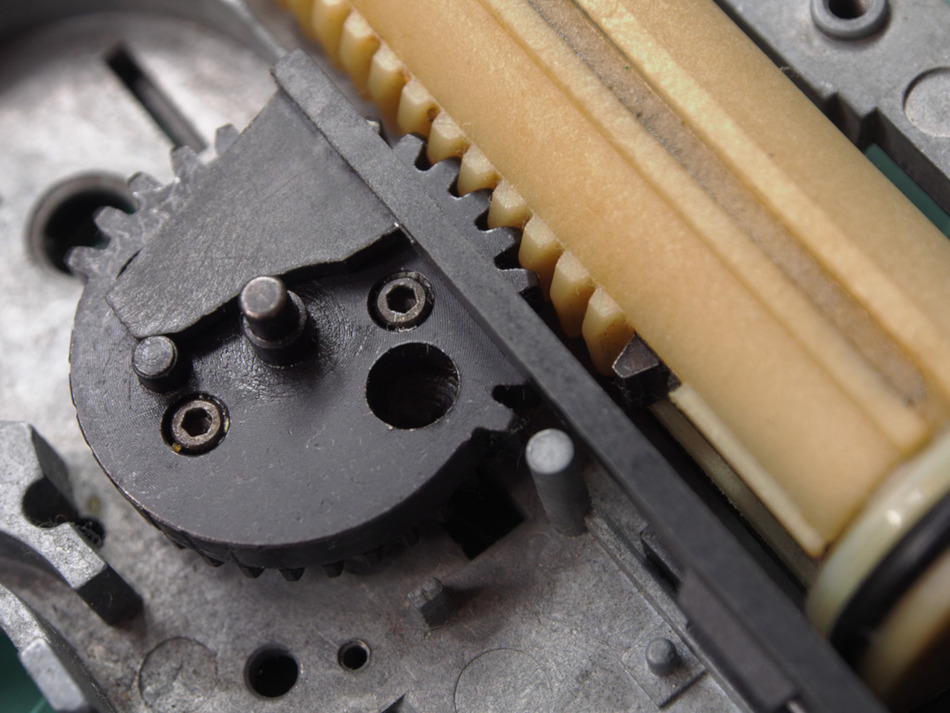

Using a ported cylinder equally an case, a sector gear with 16 teeth and a matching piston without alterations will shift dorsum plenty for the piston head to clear the ports as shown below.

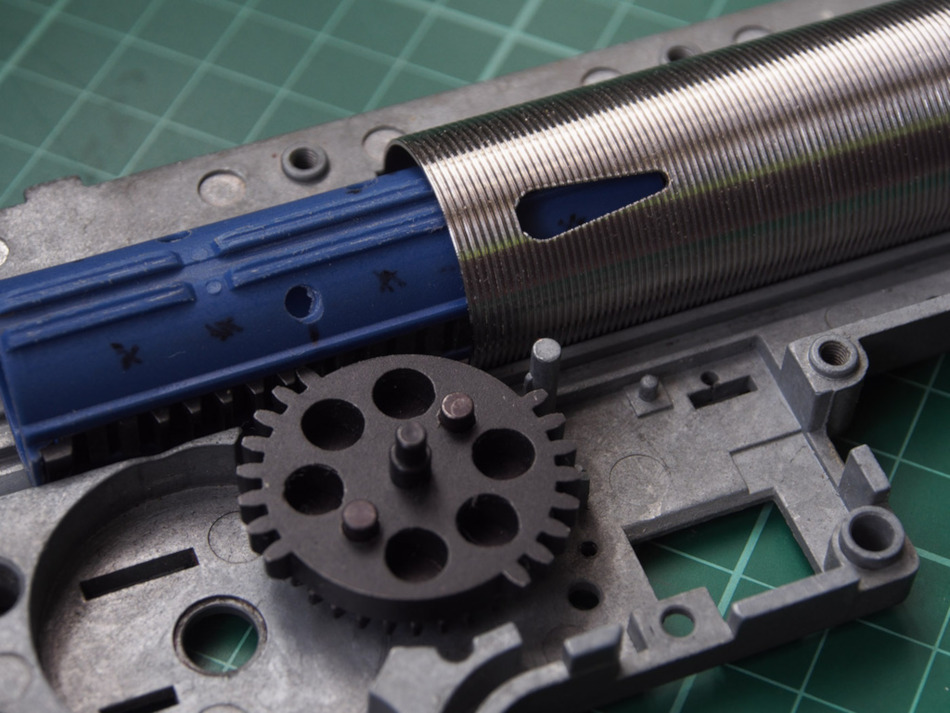

In comparison, the post-obit image shows the configuration using the same ported cylinder using our modded piston and K&G's accept on the dual sector gear.

The idea behind the ports is that, depending on barrel length, you may not need the full volume of air provided by a cylinder without ports. By placing vents for air to escape compression is delayed until information technology's needed allowing the piston to accelerate farther improving efficiency in the spring'due south transfer of power. The closer the port's location to the rear end of a cylinder the more air volume information technology tin provide for longer barrels. Ports further at the front accept express air volume and are used for brusk inner barrels.

In our case, the curt travel of our piston does non allow the piston caput to make use of the ports. Despite the ports playing no factor in our build, the brusk travel still translates to a lower book of air because we are effectively limited to a fraction of the cylinder'southward total capacity.

What this ways for our build is that nosotros are limited to running brusk barrels. In the stop this may impact our maximum range and the possible aesthetics of our AEG.

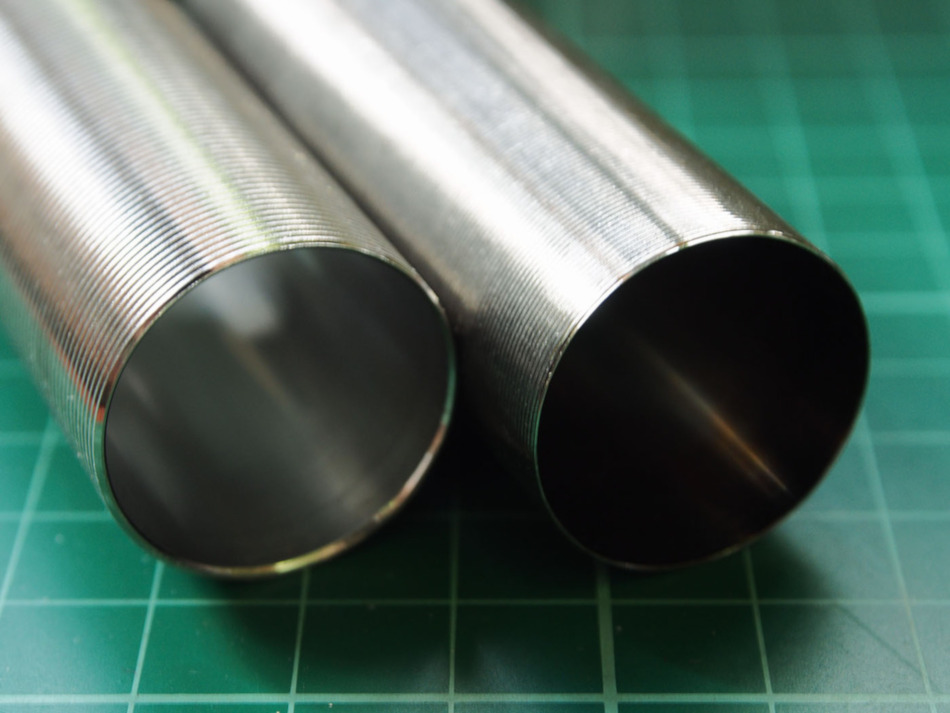

A possible solution is to adopt a bore-upwardly cylinder and cylinder head. As the name implies it is a cylinder with a slightly wider inner diameter originally used to provide more air book to propel bbs through inner barrels above 550mm in length.

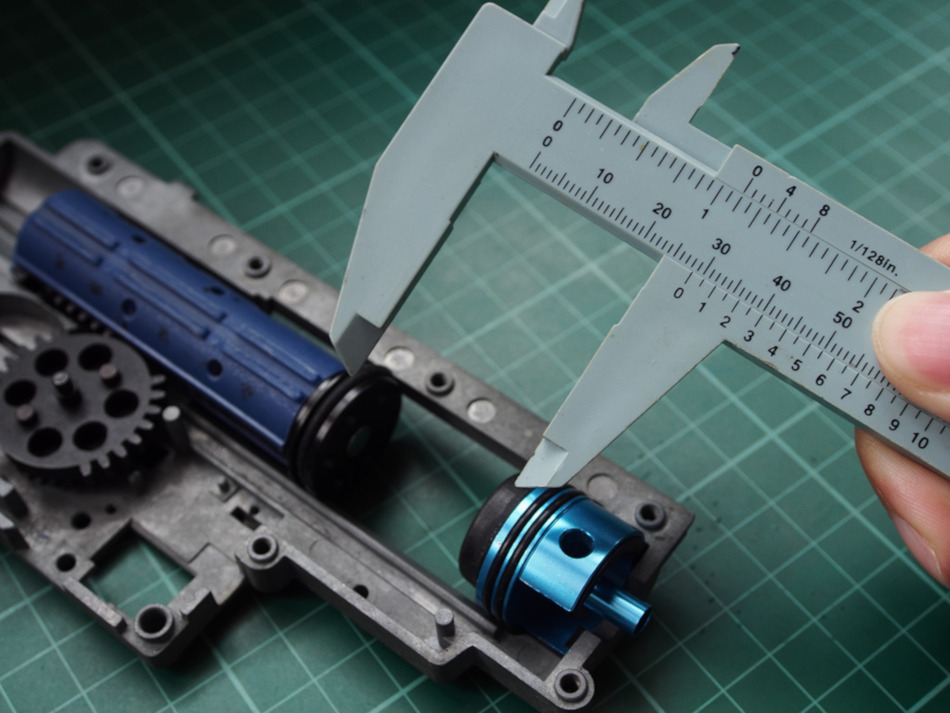

The diameter divergence between the 2 cylinders above is about one.3 millimeters. Information technology'due south 24.9 millimeters for the bore-up cylinder versus 23.6 millimeters for the standard 1. A 1.3 millimeter difference might seem small-scale, but when calculated, it translates to about an 11.32% air volume gain over the non-bore-upwards cylinder!

Book Matching

Ideally y'all will want your bbs to exit the inner barrel only before the piston head makes contact with the cylinder head. Likewise before long ways you have an over volume and the piston head will striking the cylinder head with extra unneeded force and produce a loud sound signature.

In addition the extra air from the backlog cylinder volume may cause turbulence behind the bb afterwards it exits the inner barrel that could disturb it's flight path, affecting accuracy. Also late and you may not reach the spring'due south intended velocity rating leading to poor FPS readings.

By getting measurements and using the equation πr²*H, where r is the cylinder'southward radius and H is the piston head's travel, you can calculate the air volume your system makes. Also you can employ the aforementioned equation and substitute r for the radius of the inner barrel bore, and H with the length of the inner barrel past the hop window and towards the stop where the bbs exit.

With calorie-free bbs, 0.20g to 0.25g, you volition want to maintain a ratio of 1.5 cylinder air volume to ane.0 of the barrel. In a perfect world it would be one to i, but in existent life we take to account for drag caused by friction and mass. For bbs past 0.25g you will need more than air volume to overcome elevate.

When using wide bore barrels y'all will also need to account for blow-by caused by the increased gap between the bb and the butt walls which permit more air to escape, and therefore need to push the ratio even further.

The initial ratio nosotros decide on is more than of a guide. Getting the exact ratio for the awarding can be catchy and is largely trial and error wherein you demand to use a chronograph and identify at which point the gear up up produces the highest fps readings. This is where tuning of the ports on a cylinder and the utilise of spacers come in.

For our build, we are already stripped for air volume due to the short stroke as shown above. With merely 28.5mm of piston travel it equates to nigh 12,466.91 mm³ using the formula we discussed. Because a ratio of ane.5 we need a butt with a maximum volume of almost 8,311.27 mm³. That leaves united states of america with well-nigh a 286.41 mm or 286 mm barrel length with a 6.08 mm bore diameter to make utilize of if we consider bulletin board system up to 0.25g.

Should we desire more air book to run heavier bbs or utilise a longer inner barrel, the only other upgrade we tin utilize is to use a bore up cylinder set. Running a tighter bore such as 6.04 mm as compared to half dozen.08 mm will net us almost 4 mm more length at about 290.21 mm. A small difference in my stance, but will lead to higher fps readings.

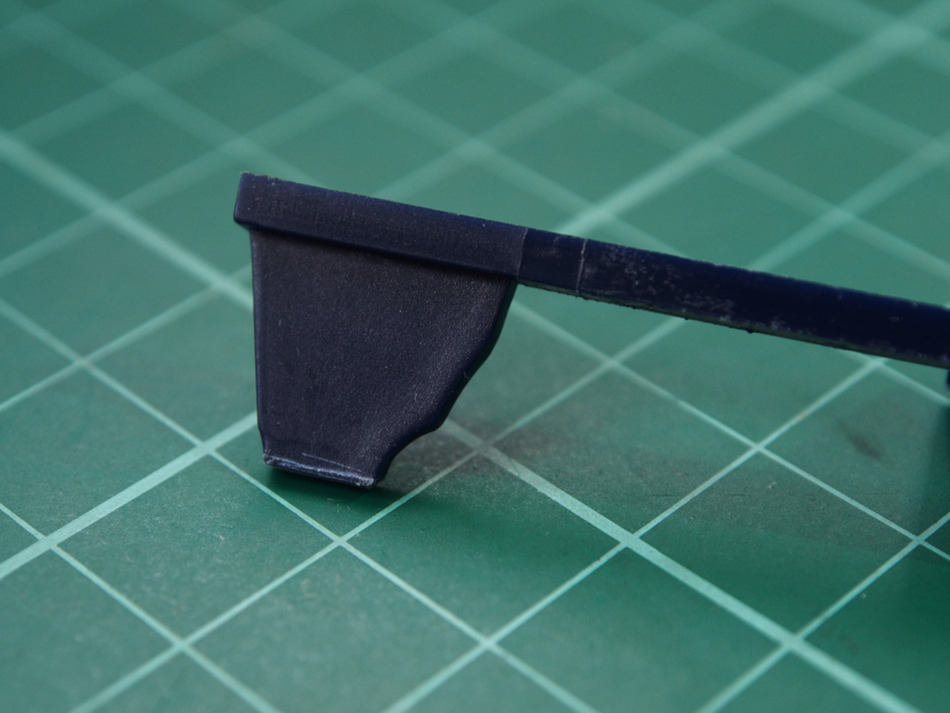

Tappet Plate

The tappet plate is a plastic arm with a fin that synchronizes the loading of bbs into the hop chamber with the cycle of the piston through a peg found on the sector gear. Depending on the fin pattern, the characteristics of feeding bulletin board system into the hop chamber can be tuned.

Siegetek Anarchism SC, the inventor of the dual sector gear suggests that the tappet plate fin be cutting to size at 11mm long. I used a Sharpie here and the X-acto pocketknife to scribe where I plan to cut.

With the tappet plate fin measuring 11mm long the nozzle chambers a bb just earlier the sector gear releases the piston. I would have liked to cut just a bit more than textile off to speed up the actuation, only the window for bb's to enter might become too brusk.

Compared to a full length fin the window for bulletin board system to climb up into the bedroom is shortened. With the nature of a dual sector gear build actuating the tappet plate twice as much per revolution compared to a conventional sector gear, that window is further decreased and may compromise feeding. Therefore the tappet plate needs to be drawn dorsum for as long as possible to ensure that feeding issues are mitigated.

Air Seal Nozzle and FPS Gains

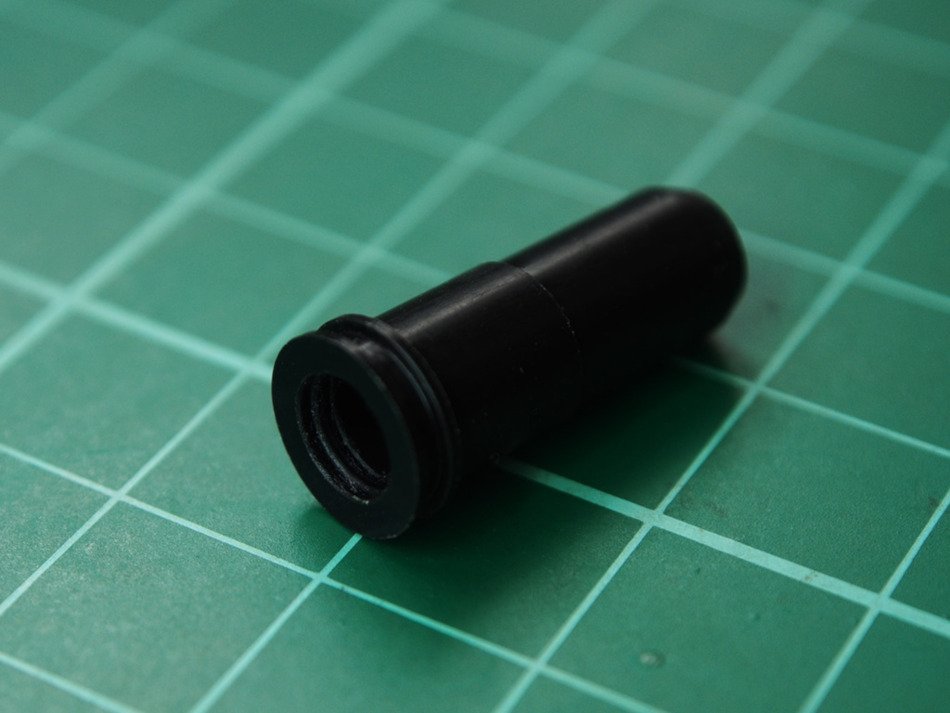

The air seal nozzle is a moving component that slides along the cylinder head's tube. Together with the tappet plate they allows bulletin board system to feed into the hop chamber without air escaping during the bb'southward firing wheel.

After letting bb'southward into the chamber the air seal nozzle pushes confronting a safe hop bucking within the hop chamber ensuring that the air transfer from the cylinder associates is air tight.

Stock air seal nozzles commonly have no o-rings and can be a source of air leaks causing drops in muzzle velocity. Withal o-rings can likewise exist a source of drag in high speed set ups so it is important to continue them clean and lubed to minimize resistance.

As far as choosing an air seal nozzle is concerned, it is simply about getting the proper length at which information technology does not impede feeding by being too long, simply not besides brusque either every bit to being unable to create a proper seal with the hop bucking found inside the hop bedchamber.

Usually the air seal nozzle is pre-measured and labeled for which model AEG it is designed to work with. Though sometimes tolerances tin be loose enough that modding the tappet plate or a different air seal nozzle becomes necessary.

Another mod involves shaving the forepart of the tappet plate that rests on the gearbox vanquish to pull the air seal nozzle further into the hop chamber creating a meliorate seal.

Summary

At this point it is fourth dimension to put everything together. We can practice a examination fit and it should look like this.

So far, we've applied a Sorbothane pad on the version 2 cylinder caput that serves to mitigate stupor and right for angle of engagement. There are different cylinder types for different barrel lengths, only in our case, the piston nosotros put together predominantly dictated the barrel length for our build. We will be running bbs not heavier than 0.25g and therefore went with a ratio of i.5 to one, which pb u.s. to a maximum barrel length of about 286 mm at a 6.08mm bore diameter.

The tappet plate was shaved downwardly at front to better sealing of the air seal nozzle with the hop bucking as to prevent air leaks during the pneumatic compression. Material was trimmed off of the fin until nosotros got a length of nigh 11mm, which was the recommended length for compatibility with dual sector gears, equally stated by Riot SC's guidelines. Components were then cleaned out to minimize resistance betwixt moving parts.

This build is my first foray into the world of dual sector gears and there's no way to tell how the parts will perform as a whole just yet. But with the preparations we've made, I am highly optimistic and confident in the time to come result. If I had to guess, the area we might need to tweak more than will most likely be the feeding characteristics of the tappet plate.

In conclusion, the key when working with the cylinder assembly is to friction match volumes to your requirements, ensure air tight seals, and prevent feeding issues by minimizing drag between moving parts.

Go along these three things in mind yous'll exist able to naturally pinpoint the areas that demand your attending, and be on your fashion to assembling great performing cylinder sets, the warrior style!

Side by side up for this build is gearbox shell grooming.

– J4

Are Version 2 and 3 Airsoft Cylinder Heads the Same

Posted by: caudillworsir.blogspot.com

0 Response to "Are Version 2 and 3 Airsoft Cylinder Heads the Same"

Post a Comment